On 1 January 2026, the port of Qingdao, controlled by Shandong Port Group, launched China’s first automatic vacuum mooring system. The technology was used to berth the container ship MSC Saudi Arabia, 366 metres long, at Qingdao’s fully automated container terminal, completing the operation in under 30 seconds. The system fully replaces traditional mooring lines and does not require personnel to be present on the quay.

The project was developed by the Liangang Innovation Team, a research group led by engineer Zhang Liangang, who was previously involved in the design of Asia’s first automated terminal. The team worked with domestic industrial suppliers to adapt the system to the characteristics of large container vessels, including units over 300 metres in length. The first operational application with an Ultra Large Container Vessel confirmed the system’s ability to handle high loads and stresses under real operating conditions.

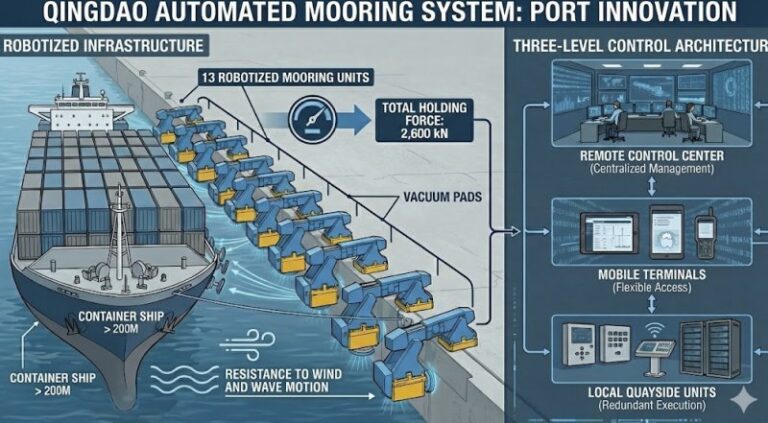

From a technical perspective, the infrastructure installed at Qingdao consists of 13 robotic mooring units equipped with vacuum pads. The simultaneous activation of the units generates a total holding force of 2,600 kilonewtons, considered sufficient to keep container ships over 200 metres in position even in windy conditions and heavy swell. The system is governed by a three-level control architecture integrating a remote control centre, mobile terminals and local units installed on the quay, enabling centralised and redundant management.

The main driver behind the introduction of the automatic vacuum mooring system is operational efficiency. Traditional mooring operations typically take between 20 and 30 minutes, while the new technology allows the berthing phase to be completed in under 30 seconds. According to estimates by the port of Qingdao, the time savings can exceed 200 hours per year per berth, making it possible to accommodate up to ten additional ships annually without any infrastructural expansion.

A second key factor is workplace safety. Mooring with ropes is considered one of the most critical phases of port operations due to the risk of line failure and the so-called snap-back effect. Eliminating mooring lines and removing personnel from the quay during berthing drastically reduces exposure to this type of risk, in line with the accident reduction objectives promoted by the Chinese port authorities.

The system also has environmental implications. Shorter manoeuvring times lead to lower emissions from ships during approach and berthing. In addition, greater vessel stability alongside the quay allows cranes to operate more continuously, reducing overall port stay and improving terminal resource utilisation.

The operation of the system is based on a fully automated sequence. As the vessel approaches, optical and laser sensors detect the hull position. The robotic units then extend their arms towards the ship’s side, activating the vacuum pads that create suction and secure adhesion to the hull within seconds. Once attachment is complete, the system monitors wind, waves and currents in real time, adjusting the holding force to compensate for movements and limit surge, a typical issue with traditional mooring.

The Qingdao experience could become a reference model for the adoption of line-free mooring systems in other domestic ports, particularly at highly automated terminals with intensive container traffic. The container terminal is one of China’s main testing grounds for smart port technologies. It is already characterised by a high level of automation for yard equipment and cranes, as well as the use of low-emission solutions to power port machinery.