At a time when much of Europe is paralysed by heavy snowfall, an active de-icing system based on heat pipes and automatic control entered service on 1 January 2026 on the Leibo section of the Leshan–Xichang motorway, in China’s Sichuan province. The technology has been installed at the points most exposed to snow and ice along the mountainous stretch between Dafengding and Gudui and coincides with the opening to traffic of the Mabian–Zhaojue section, which took place at midnight between 31 December 2025 and 1 January 2026. The operational objective is to ensure winter traffic continuity on a corridor characterised by a high concentration of bridges and tunnels, while reducing response times and dependence on mechanical snow removal and chemical agents.

The context is a 152-kilometre artery built to four-lane dual-carriageway motorway standards, with a design speed of 80 kilometres per hour and a bridges-and-tunnels ratio of 82%, crossing steep slopes, deep gorges and areas of high geological complexity. The declared investment for this section amounts to 335.32 billion yuan, equivalent to around €46 billion, with an average cost of about 2.2 billion yuan per kilometre. Bringing the motorway into service has a direct impact on accessibility for the counties of Leibo, Meigu and Zhaojue, which for the first time gain continuous and more predictable motorway access even during the winter months.

The decision to adopt an active de-icing system is linked to a climate profile combining recurring snow accumulation and frequent ice formation, with temperatures that can fall to minus 15 degrees Celsius during the harshest periods. In this setting, critical points are not evenly distributed along the route but are concentrated in locations typical of a mountain environment: tunnel entrances and exits, uphill ramps near portals, viaduct sections exposed to wind and areas subject to prolonged shading. These are conditions in which the road surface can fluctuate rapidly around freezing point, encouraging the formation of black ice and reducing grip without obvious visual warning for drivers.

The project sits within a complex industrial and institutional supply chain, marking the transition from a pioneering phase to full-scale application. The client role is held by Shuodao Investment Group, a public group of Sichuan province active in developing major regional transport infrastructure, while investment in and operation of the motorway fall under the remit of the Sichuan High Speed Highway Construction and Development Group. Design of both the motorway and the de-icing technologies was entrusted to the Sichuan Highway Design Institute, which had previously tested similar systems on provincial roads in pilot contexts and has now transferred those solutions to a high-traffic motorway with a significant presence of industrial vehicles. Construction of the project, including installation of the heat pipes beneath the road surface, was carried out by the Sichuan Road and Bridge Construction Group, a contractor specialising in large-scale works in mountainous environments.

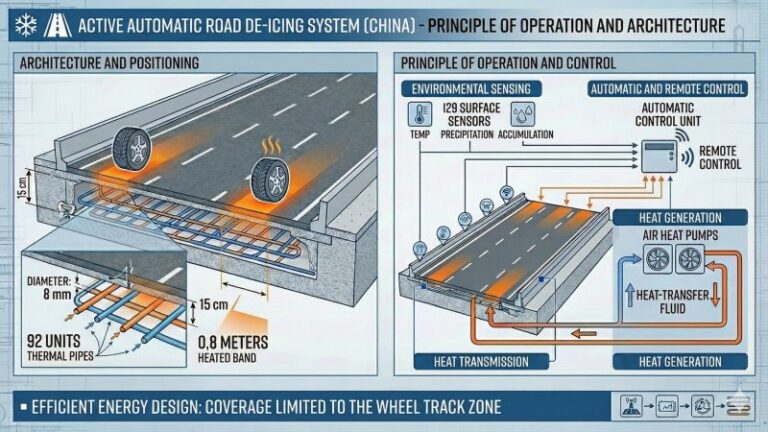

The system has been applied selectively to around 7.5 kilometres identified as high risk, with the thermal circuits covering a total length of 2,374 metres distributed across 27 segments. The architecture includes 92 heat pipe units with a diameter of 8 millimetres, installed at a depth of 15 centimetres below the carriageway. A key energy design choice is the limitation of coverage to the wheel-track zone. For each lane, the heated strip is about 0.8 metres wide, concentrating thermal input where it is most effective for vehicle dynamics and reducing the power required compared with heating the entire carriageway. The aim is not to raise the overall pavement temperature, but to maintain a thermal window just above freezing along the rolling paths, preserving vehicle stability and preventing the formation of ice sheets.

The operating principle is based on a circuit using a heat-transfer fluid warmed by air-source heat pumps. When conditions favour snow and ice formation, the system brings the fluid to a temperature between 50 and 60 degrees Celsius and circulates it through the buried pipes. Heat is transferred by conduction through the pavement layers to the surface, where control logic seeks to keep the heated strip at around one to two degrees above zero. Operating in this range prevents surface moisture from freezing and initiates snow melt on contact, while limiting energy consumption and thermal stress on the asphalt layers. The system is designed to melt up to 20 centimetres of snow in about five hours of continuous operation. During very heavy snowfall, it is intended to work in combination with mechanical equipment, preventing refreezing and making removal more effective.

Automation is a central element of the project. Along the section, 129 sensors monitor surface temperature and precipitation or accumulation conditions. Data are fed into a control centre that processes parameters using automatic regulation logic, supported by a local meteorological monitoring network covering a five-kilometre radius. The system can anticipate activation when temperature trends indicate a risk of icing and modulate power once the surface stabilises, avoiding unnecessary cycles. Management thus shifts from a reactive approach based on alerts and human intervention to a preventive strategy that activates the system when the probability of freezing exceeds a predefined technical threshold.

In terms of maintenance, the system is remotely monitored and features automatic fault signalling, reducing diagnosis and intervention times. Design specifications provide for a maximum technical response window of two hours in the event of a failure, a relevant parameter on mountainous motorways where grip conditions can deteriorate rapidly, particularly in transition zones between tunnels and open sections. System availability, in terms of power supply and redundancy, therefore becomes an integral part of the winter service level, alongside snowplough fleets.

Comparison with traditional methods clarifies the investment rationale. Mechanical removal and the use of salts or chemical agents remain widespread solutions, but in mountain sections they present structural limitations: mobilisation times, operator exposure to hazardous conditions, reduced effectiveness on black ice and corrosive impacts on bridges, barriers and structural components. A thermal system reduces the use of chemicals and stabilises the road surface. It represents a paradigm shift, moving focus from removing the event to preventing its formation. From a cost perspective, the burden shifts partly from labour and consumables to energy expenditure and electromechanical maintenance, making selective installation at the most critical points a central design choice.

Another technical aspect concerns interaction with heavy traffic. Repeated loads and shear stresses on the pavement require pipe depth and protection to be compatible with continuous transit of industrial vehicles. Increasing installation depth to 15 centimetres and adopting an 8-millimetre diameter address this requirement, ensuring greater robustness and long-term reliability. Concentrating heating on the wheel tracks also exploits snow compaction generated by traffic, accelerating the transition to a moist, unfrozen surface that is easier to manage in terms of grip.

The Leshan–Xichang motorway also represents a case of integration between alignment choices and climate risk management. Such a high bridges-and-tunnels ratio reduces land take but multiplies microclimatic transitions, especially between enclosed environments and wind-exposed sections. It is precisely at these transitions that ice formation is most frequent. The de-icing system has therefore been designed in coordination with drainage, ditches and safety devices, ensuring that meltwater does not stagnate and refreeze in shaded downstream areas.

From a logistics continuity perspective, the most significant effect is the reduction of winter closures on a corridor serving inland and mountainous areas. Shorter journey times are accompanied by greater service predictability, a crucial factor for freight transport. For time-sensitive flows such as fresh agricultural products, value lies not only in speed but in reduced variability linked to weather events. Infrastructure that maintains grip at the most critical points enables more stable flow management, cutting prolonged stops and congestion upstream of interchanges and service areas.

With operations starting in January 2026, the system now enters its field verification phase. Surface temperature stability, behaviour under wind and strong thermal gradients, management of meltwater and component reliability in a mountain environment will be decisive in assessing replicability on similar infrastructure. In this sense, the project serves as a testbed for the evolution of winter motorway management technologies in complex contexts, where safety, operational continuity and sustainability must be addressed as a single technical challenge.

M.L.