It may seem paradoxical, but filing for preliminary insolvency does not necessarily signal the end of a business; it can serve as a legal tool to mark the beginning of a restructuring process aimed at consolidating, strengthening and ensuring the long-term sustainability of a company. This is the course taken by Helrom in July 2025 under German legislation. The company is a specialist operator in the intermodal rail transport of semi-trailers.

To dispel any legitimate doubts about its future outlook, the company is reaffirming and expanding its plans, including the new route scheduled for September 2025 between Katowice, in south-western Poland, and Düsseldorf, in western Germany. This will also mark Helrom's first cross-border link into Poland. In just five years since its founding, the German company has developed an intermodal network stretching from Düsseldorf to the south-east as far as Budapest, with stops in Regensburg, Vienna and Lébény in Hungary, while to the south it connects with the terminals in Trento and Verona (Sommacampagna), thanks to partnerships with several rail operators.

What has enabled Helrom to carve out a significant share of the market in such a short time? The answer lies in the technology it has adopted, which allows the rail transport of semi-trailers without requiring additional infrastructure for rail/road transhipment operations. This is made possible by a horizontal loading technique that only needs level tracks flush with the road surface. In addition, the company has designed and developed an innovative pocket wagon, enabling even non-craneable semi-trailers—the vast majority—to travel by rail.

The Helrom wagon is articulated: the two pockets rest on three bogies and can accommodate three standard road semi-trailers. The loading and unloading technique is equally innovative, optimising operations without the need for fixed installations and reducing times: a full train can be loaded and unloaded within a couple of hours. All movements on the wagon are performed by a pneumatic system powered by compressed air generated by a pump mounted on the central bogie of each wagon, with an electrical conduit supplying power. When fully loaded, these wagons have a mass of 120 tonnes and can travel at speeds of up to 120 km/h, more than adequate for freight trains.

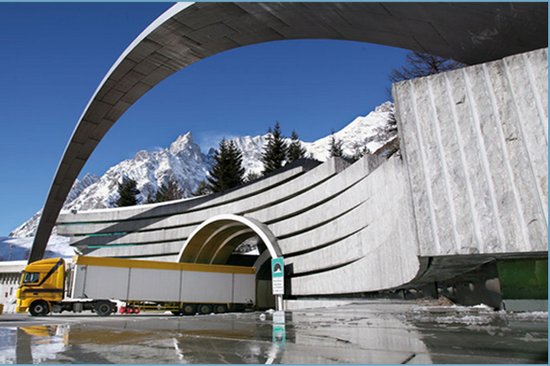

This technology invites comparison with the Modalohr system, chosen for the alpine rail motorway between Orbassano, near Turin, and Aiton in France, close to Chambéry. At first glance, it appears to employ the same horizontal loading strategy (with or without the road tractor), but in this case it requires a dedicated infrastructure with specialised terminals equipped with ground-based hydraulic systems to open the wagon pockets. The Modalohr system is therefore limited to dedicated terminals, but still offers the advantage of handling all standard semi-trailers.

Another solution designed to accommodate all non-craneable semi-trailers is the Nikrasa system, offered by TX Logistik. Here, the semi-trailers are placed on a transport platform that is then lifted by cranes and transferred to the railway. It is only with the current version 3.0 of the system—lighter than its predecessors, weighing less than three tonnes—that it has become simpler and more flexible, no longer requiring external platforms to handle the vehicles.

Piermario Curti Sacchi